|

equipment

|

explanation

|

Sodium Pump Seal Mock-Up Model

|

Monju Peculiar Maintenance Training Models

Sodium Pump Mechanical Seal Mock-Up Training Model

Though a mechanical sodium pump has a mechanical seal for sealing of the pump shaft, its maintenance work requires proficiency in the technology since the structure of the seal part is complicated. The mock-up training model for the Monju secondary sodium pump is useful for progressing theoretical understanding and for increasing workerfs skill. By using this model, trainees are able to experience practical maintenance skills relating to dismantling and assembling works of seal parts under near-actual working condition.

|

Fuel Handling System Training Model

|

Fuel Handling System Training Model

The fuel handling operation mode of Monju is distinguished into various modes: a spent fuel and a new fuel handling operation modes, a spent fuel washing treatment operation mode, a spent fuel storage operation mode and so on. Itfs difficult for operators to systematically comprehend the equipmentfs motion in these operational modes by reading each document.

Since this training model is a full scope type training model and is duplicated at scale of one in twelve, trainees can understand each operation modefs motion easily by viewing directly.. |

Control Rod Driving Model

|

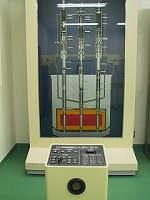

Control Rod Driving Mechanism Training Model

To avoid the occurrence of a structural common mode failure in the motion of a control rod driving mechanism (CRDM), Monju has three types of CRDM: a fine control rod driving mechanism (FCRDM), a coarse control rod driving mechanism (CCRDM) and backup control rod driving mechanism (BCRDM). As shown in the picture, the structure of each CRDM is duplicated faithfully and is revealed with a see-through structure like a birdfs-eye view. Also, each CRDM model can offer each stepfs motion on all operation modes of CRDM, respectively. |

Upper Core Fuel Handling Machine Model

|

Upper Core Fuel Handling Machine Training Model

The fuel handling machine (FHM) is installed on the upper core structure as one of the preparation works for fuel handling work in the reactor core. At that time, a skillful technique is required in order to carry out safely its installation work because alignment work for heavy weight components, like the FHM, at the narrow space on the upper core part is very difficult. This model traces the real machinefs size in the radial direction and trainees can experience its installation work realistically. |

Rapture Disk Handling Model

|

Rapture Disk Handling Training Model

The Rupture disk provided in preparation for sodium and water reaction at the steam generator will be exchanged periodically. In this work, itfs necessary for workers to have expert skill since a disk is ruptured very easily due to its thinness (ca. 1mm). As nobody is experienced in this work actually, this training is very fruitful for workers. |

Conventional Maintenance Technologies Training Models

For learning the conventional maintenance technologies regarding mechanical and electrical technologies, the following four training models are furnished:

EWater loop training model: Overhaul maintenance of rotating machinery contained pump dismantling and assembling

EPower supply panel training model: Overhaul maintenance of power cubic-panel and power control center

EControl and instrumentation Training Models: Optimization of PID control parameters (principles of feedback control)

ENon destructive inspection tools: a Liquid Penetrant Testing (PT), Radiographic Testing (RT) and Ultrasonic Testing (UT) |

|

|

| Some cut-way mock-ups of major plant equipment are also furnished in order to reinforce theoretical understanding. |

|

|

|

|

Mock-up of upper core stracture |

Mock-up of pump |

|

|

|

Mock-up of pump upper side |

Mock-up of electromagnetic pump |

|